Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

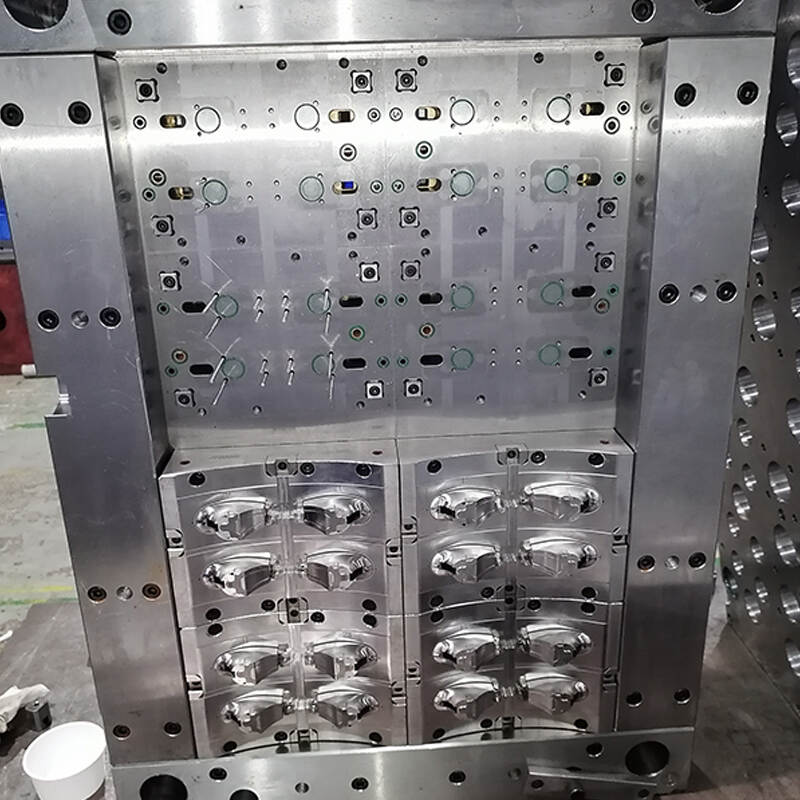

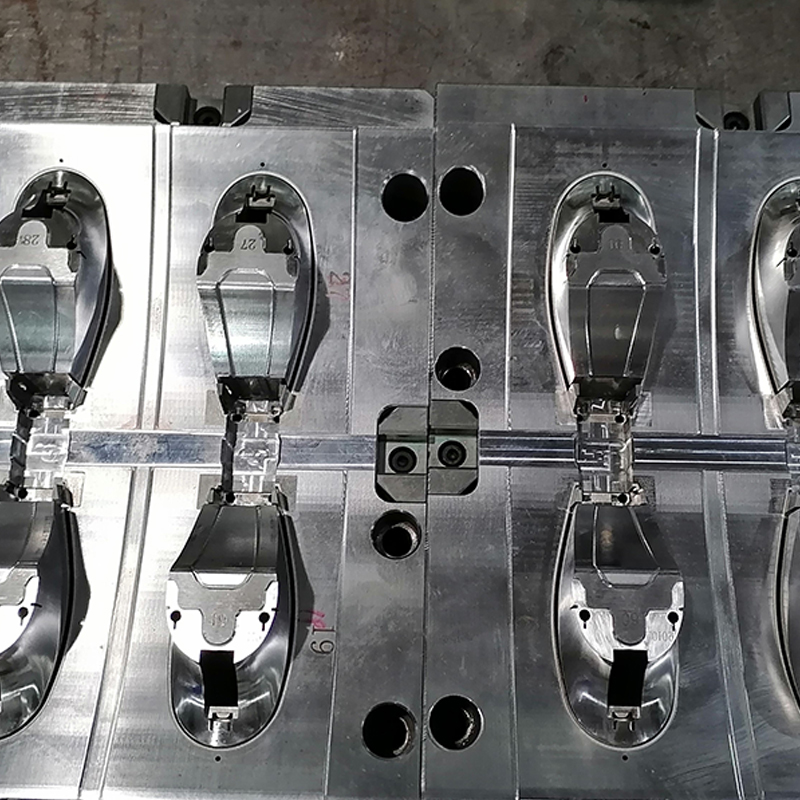

Sprayer Injection Mould

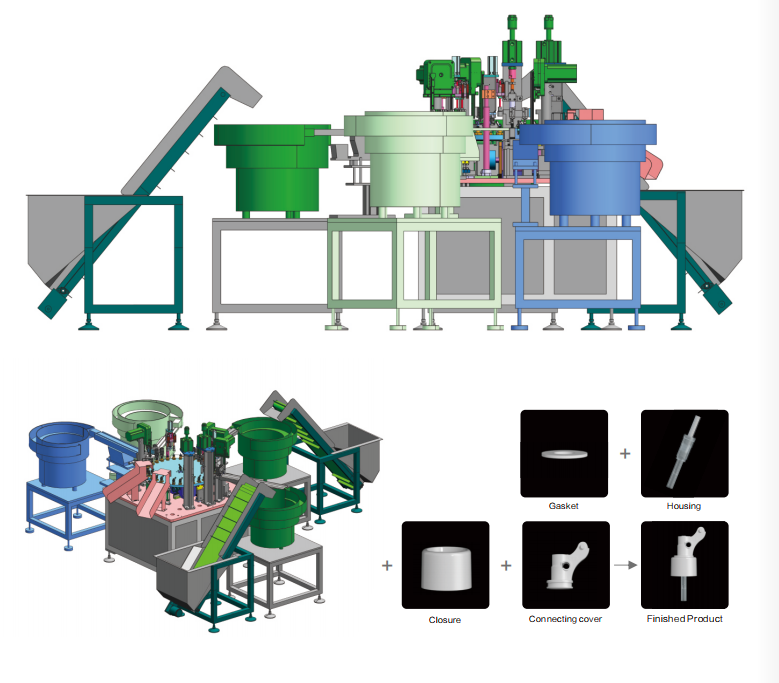

The sprayer injection mold by Songrock, meticulously crafted in Ningbo, Zhejiang, China, embodies precision engineering and innovation. Tailored to meet diverse customer specifications, this mold exemplifies excellence in design, material quality, and functionality. With a focus on durability, efficiency, and user-friendliness, Songrock's sprayer injection mold stands as a testament to cutting-edge manufacturing.

Description

Crafted with expertise and attention to detail, the sprayer injection mold from Songrock serves as the cornerstone for producing high-quality sprayer components. Designed to meet the demands of various industries, including cosmetics, household cleaning, and automotive, this mold ensures consistent and reliable performance. Utilizing advanced materials and manufacturing techniques, Songrock delivers a product that exceeds expectations in terms of durability, precision, and ease of use.

Product Specification

|

Birthplace |

Ningbo, Zhejiang, China |

|

Brand |

Songrock |

|

Product Material |

Steel |

|

Plastic Material |

PP/PE/PET (all plastics) |

|

Product |

Designed and developed according to customers' requirements |

|

Regular-size frame |

45# steel, 50# steel |

|

Mould cavity |

S136, H13, and others according to mold product characteristics |

|

Mould surface |

Polished or sprayed with anti-rust paint according to the customer's requirements |

|

Mold heat treatment |

Cavity sleeve |

|

Mould Life |

Guarantee 100w mold |

|

Design Software |

UG |

|

Packing and shipping |

Packed in a wooden case for export, export molds coated with rust inhibitor, spare parts shipped with molds. |

Product Features and Advantages

1. Precision Engineering: The sprayer injection mold incorporates advanced mold cavity materials, such as S136 and H13 steel, ensuring precise and uniform product formation with each injection cycle.

2. Customization Options: Tailored to individual requirements, the mold allows for flexibility in design and specifications, accommodating diverse product variations and configurations.

3. Enhanced Durability: Constructed from high-quality 45# and 50# steel, the mold boasts exceptional strength and resilience, guaranteeing prolonged service life and minimal maintenance requirements.

4. Optimized Surface Finish: With options for polished surfaces or anti-rust paint coatings, the mold ensures smooth and flawless product finishes, enhancing aesthetic appeal and consumer satisfaction.

5. Efficient Heat Treatment: Incorporating cavity sleeve heat treatment, the mold facilitates efficient heat dissipation, preventing deformations and prolonging tooling life.

6. Compatibility and Versatility: Compatible with various plastic materials, including PP, PE, and PET, the mold offers versatility in material selection, accommodating a wide range of application needs.

7. Seamless Integration with Design Software: Designed for compatibility with industry-standard software like UG, the mold streamlines the design-to-production process, facilitating seamless integration and efficient workflow management.

Benefits

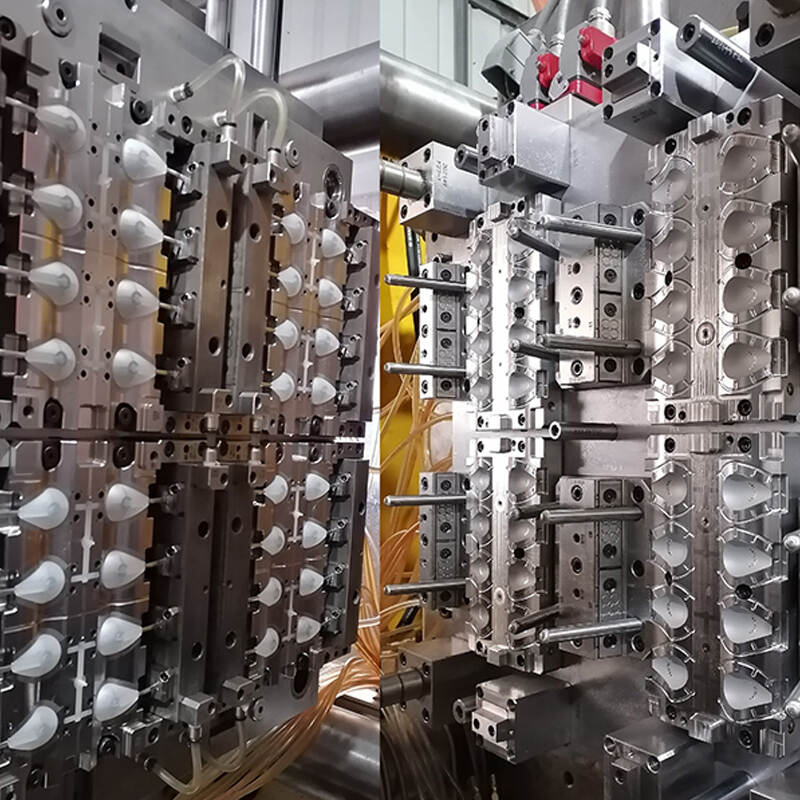

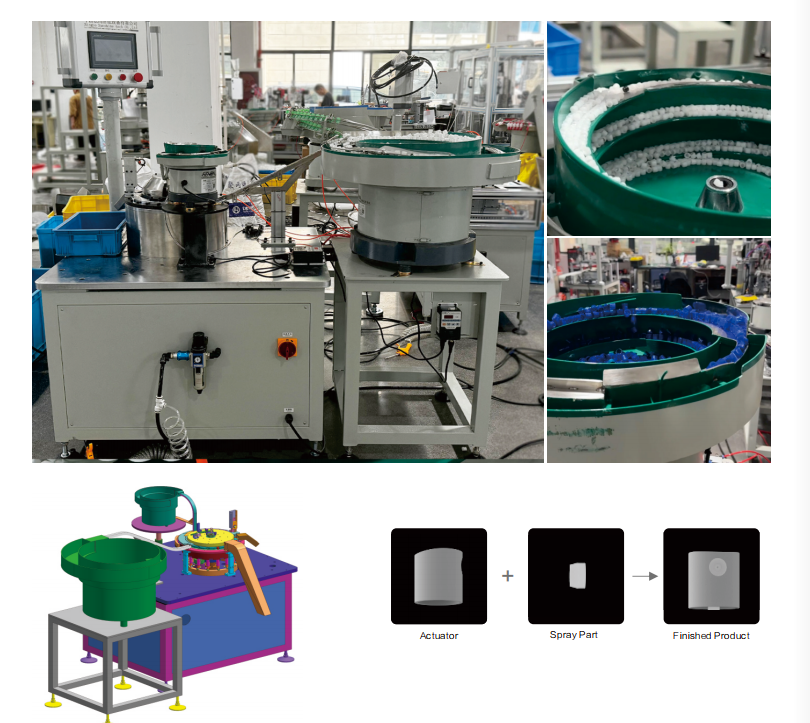

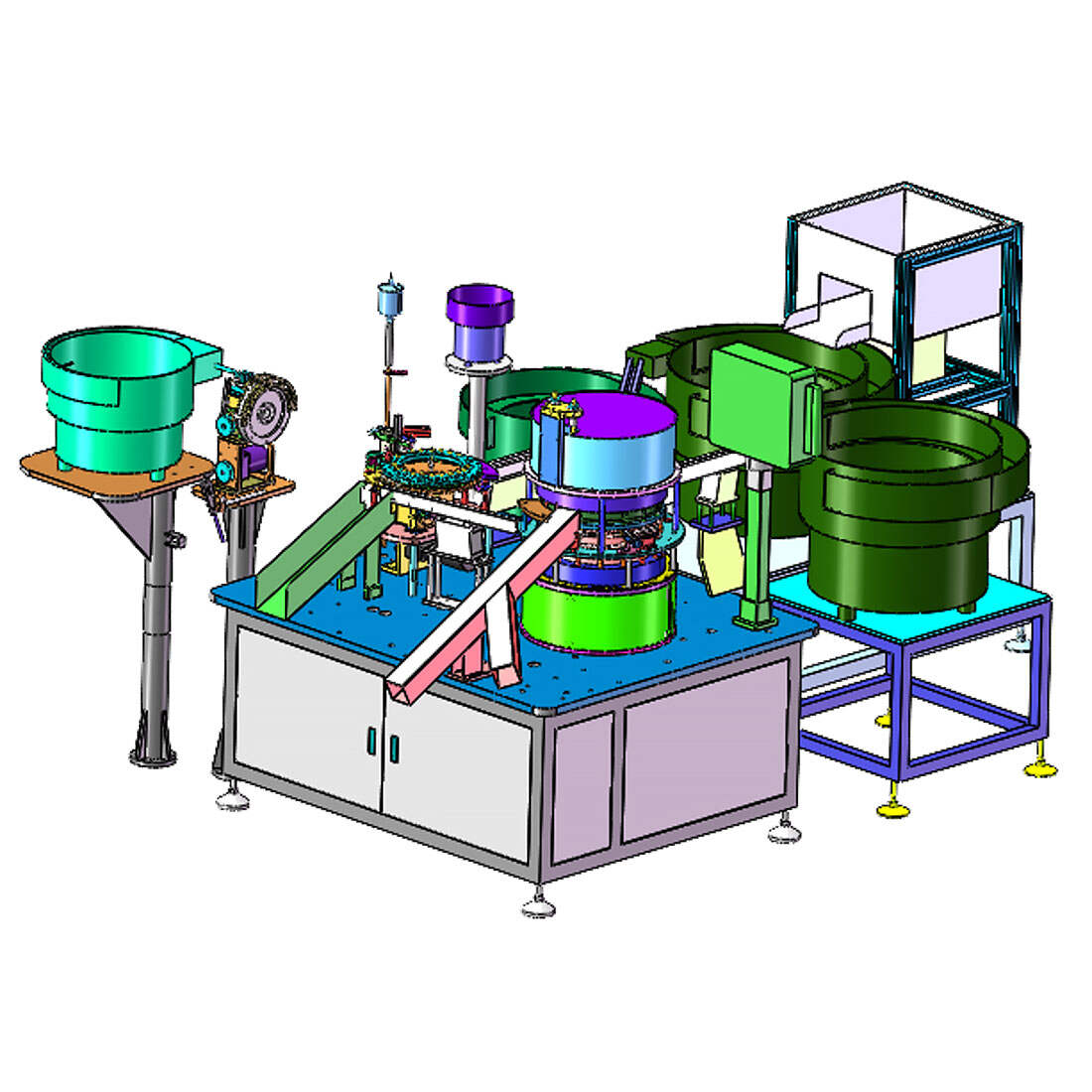

This factory boasts 60 sets of injection molding machines, over 80 sets of automatic assembly machines, and a workforce exceeding 120 production and technical employees. Additionally, it is equipped with advanced and professional technical equipment for product research and development, mold design, steel manufacturing, automatic injection molding, automatic assembly, and high-precision inspection. Our primary production encompasses daily use accessories such as plastic trigger sprayers, lotion pumps, mist sprays, cream pumps, foam pumps, and caps, alongside other personal care packaging products including plastic bottles, airless bottles, essential oil bottles, glass bottles, and skincare sets.